Nikon Z 800mm f6.3 VR S review

Nikon releases the NIKKOR Z 800mm f/6.3 VR S, a super-telephoto prime lens for the Nikon Z mount system

Accsoon M1 HDMI recorder review

Hamamatsu videos

Image Sensors World Go to the original article...

Hamamatsu has published new videos on their latest products and technologies.

Mini Spectrometers: What are mini-spectrometers and how can they be used in the medical industry?

Canon Group bolsters Label & Packaging growth strategy with acquisition of Edale

Better Piezoelectric Light Modulators for AMCW Time-of-Flight Cameras

Image Sensors World Go to the original article...

A team from Stanford University's Laboratory for Integrated Nano-Quantum Systems (LINQS) and ArbabianLab present a new method that can potentially convert any conventional CMOS image sensor into an amplitude-modulated continuous-wave time-of-flight camera. The paper titled "Longitudinal piezoelectric resonant photoelastic modulator for efficient intensity modulation at megahertz frequencies" appeared in Nature Communications.

Intensity modulators are an essential component in optics for controlling free-space beams. Many applications require the intensity of a free-space beam to be modulated at a single frequency, including wide-field lock-in detection for sensitive measurements, mode-locking in lasers, and phase-shift time-of-flight imaging (LiDAR). Here, we report a new type of single frequency intensity modulator that we refer to as a longitudinal piezoelectric resonant photoelastic modulator. The modulator consists of a thin lithium niobate wafer coated with transparent surface electrodes. One of the fundamental acoustic modes of the modulator is excited through the surface electrodes, confining an acoustic standing wave to the electrode region. The modulator is placed between optical polarizers; light propagating through the modulator and polarizers is intensity modulated with a wide acceptance angle and record breaking modulation efficiency in the megahertz frequency regime. As an illustration of the potential of our approach, we show that the proposed modulator can be integrated with a standard image sensor to effectively convert it into a time-of-flight imaging system.

Two new papers on 55 nm Bipolar-CMOS-DMOS SPADs

Image Sensors World Go to the original article...

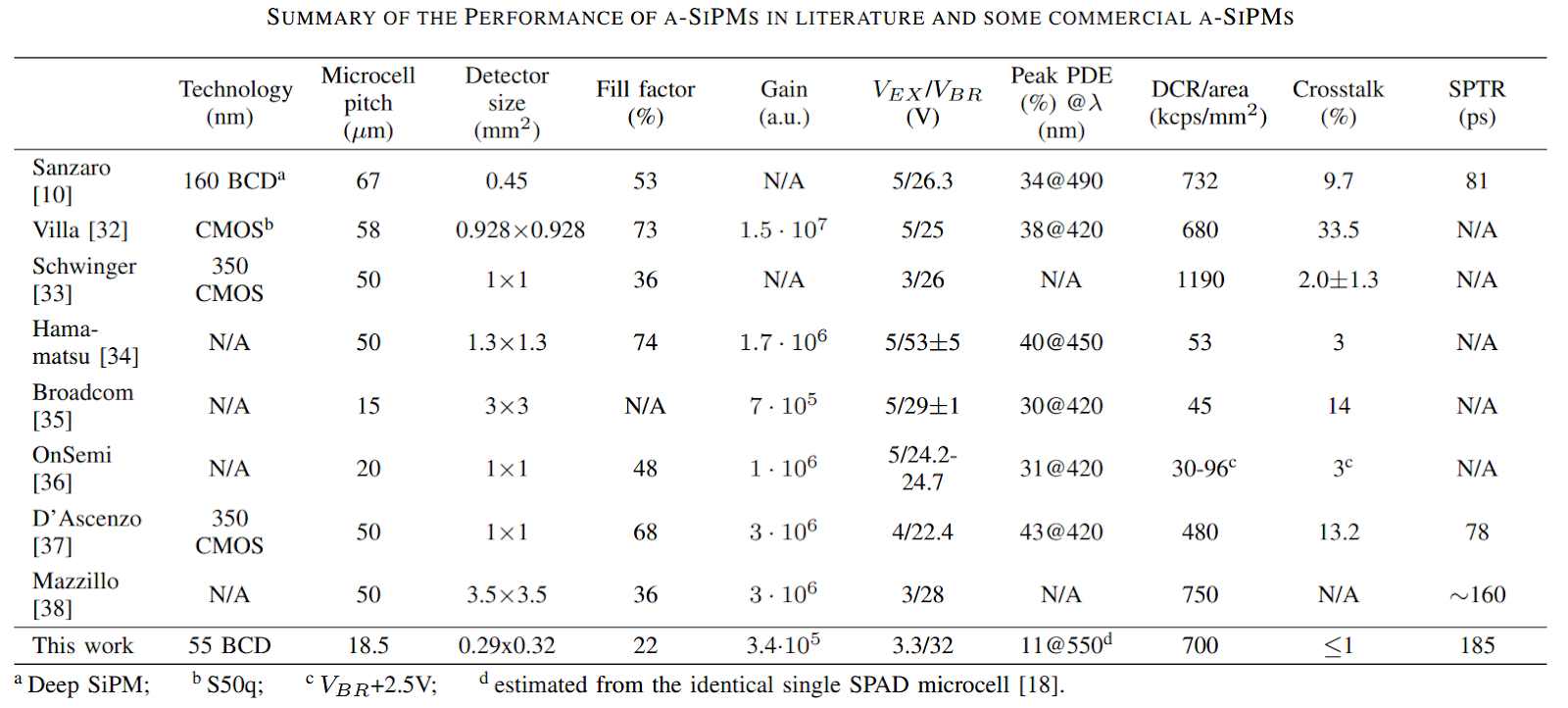

The AQUA research group at EPFL together with Global Foundries have published two new articles on 55 nm Bipolar-CMOS-DMOS (BCD) SPAD technology in the upcoming issues of IEEE Journal of Selected Topics in Quantum Electronics.

Engineering Breakdown Probability Profile for PDP and DCR Optimization in a SPAD Fabricated in a Standard 55 nm BCD Process

On Analog Silicon Photomultipliers in Standard 55-nm BCD Technology for LiDAR Applications

Product Videos: STMicro and Airy3D

Image Sensors World Go to the original article...

Low power, low noise 3D iToF 0.5 Mpix sensor

VD55G0 Consumer Global Shutter 0.4Mpix for Windows Hello Login

DepthIQ from AIRY3D

Canon Files Annual Report on Form 20-F for the Year Ended December 31, 2021

Black Phosphorus-based Intelligent Image Sensor

Image Sensors World Go to the original article...

Seokhyeong Lee, Ruoming Peng, Changming Wu & Mo Li from U-Dub have published an article in Nature Communications titled "Programmable black phosphorus image sensor for broadband optoelectronic edge computing".

Our blog had advertised a pre-print version of this work back in November 2021: https://image-sensors-world.blogspot.com/2021/11/black-phosphorus-vision-sensor.html.

Abstract: Image sensors with internal computing capability enable in-sensor computing that can significantly reduce the communication latency and power consumption for machine vision in distributed systems and robotics. Two-dimensional semiconductors have many advantages in realizing such intelligent vision sensors because of their tunable electrical and optical properties and amenability for heterogeneous integration. Here, we report a multifunctional infrared image sensor based on an array of black phosphorous programmable phototransistors (bP-PPT). By controlling the stored charges in the gate dielectric layers electrically and optically, the bP-PPT’s electrical conductance and photoresponsivity can be locally or remotely programmed with 5-bit precision to implement an in-sensor convolutional neural network (CNN). The sensor array can receive optical images transmitted over a broad spectral range in the infrared and perform inference computation to process and recognize the images with 92% accuracy. The demonstrated bP image sensor array can be scaled up to build a more complex vision-sensory neural network, which will find many promising applications for distributed and remote multispectral sensing.

It is now peer reviewed and officially published as an open access paper: https://www.nature.com/articles/s41467-022-29171-1

Peer review report and authors' responses are also publicly available. In particular, it is interesting to see the response to some comments and about pixel non-uniformities, material stability during etching and longevity of the sensor prototype.

Some lightly edited excerpts from the reviews and authors responses below:

Reviewer: The optical image of the exfoliated flake clearly shows regions of varying thickness. How did the authors ensure each pixel is of the same thickness?

Authors: The mechanically exfoliated bP has several regions with different thicknesses. We fabricated all the pixels within a large region with uniform optical contrast, as outlined by the red dotted line, indicating uniform thickness. The thickness of the region is also confirmed with atomic force microscopy.

Reviewer: There is hardly any characterisation data provided for the material. How much of it is oxidised?

Authors: The oxidation of bP, it is indeed a concern. To mitigate that, we exfoliated and transferred bP in an Ar-filled glovebox. The device was immediately loaded into the atomic layer deposition (ALD) chamber to deposit the Al2O3 / HfO2 /Al2O3 (AHA) multilayers, which encapsulate the bP flake to prevent oxidation and degradation. This has been a practice reported in the literature, which generally leads to oxidation of only a few layers. Thanks to the 35 nm thick AHA encapsulation layer, our device shows long-term stability with persistent electrical and optical properties for more than 3 months after fabrication. We discuss that in the response to question 7. Furthermore, Raman spectroscopy shows no sign of Px Oy or Hx POy forming during the fabrication process. Thus, we expect that the oxidation of bP flake is no more than 3 layers (or 1.5 nm), which, if any, marginally affects the optical and electrical properties of the bP-PPT device.

Reviewer: Why did the authors focus only on the IR range when the black phosphorus can be even more broadband into the visible at the thickness used here?

Authors: The photoresponsivity of black phosphorus certainly extends to the visible band. We have

utilized both the visible and the IR range by engineering the device with the AHA stack: IR light to input images for optoelectronic in-sensor computing; visible light to optically program the device by activating the trapped charges and process the encoded images such as pattern recognition.

Reviewer: How long do the devices keep working in a stable manner?

Authors: We agree with the reviewer that more lifetime measurement data is important to ensure the

stability of the device’s operation. We have evaluated the performance of the bP-PPT devices over a long period of time (up to 3 months) ... the gate modulation, memory window, on-off ratio, and retention time of our devices remain consistent even 3 months after they were fabricated.

In today's day and age of Twitter, it's refreshing to see how science really progresses behind the scenes --- reviewers raising genuine concerns about a new technique; authors graciously accepting limitations and suggesting improvements and alternative ways forward.

Sony Cyber-shot P1 retro review

“NIKKOR – The Thousand and One Nights (Tale 81) has been released”

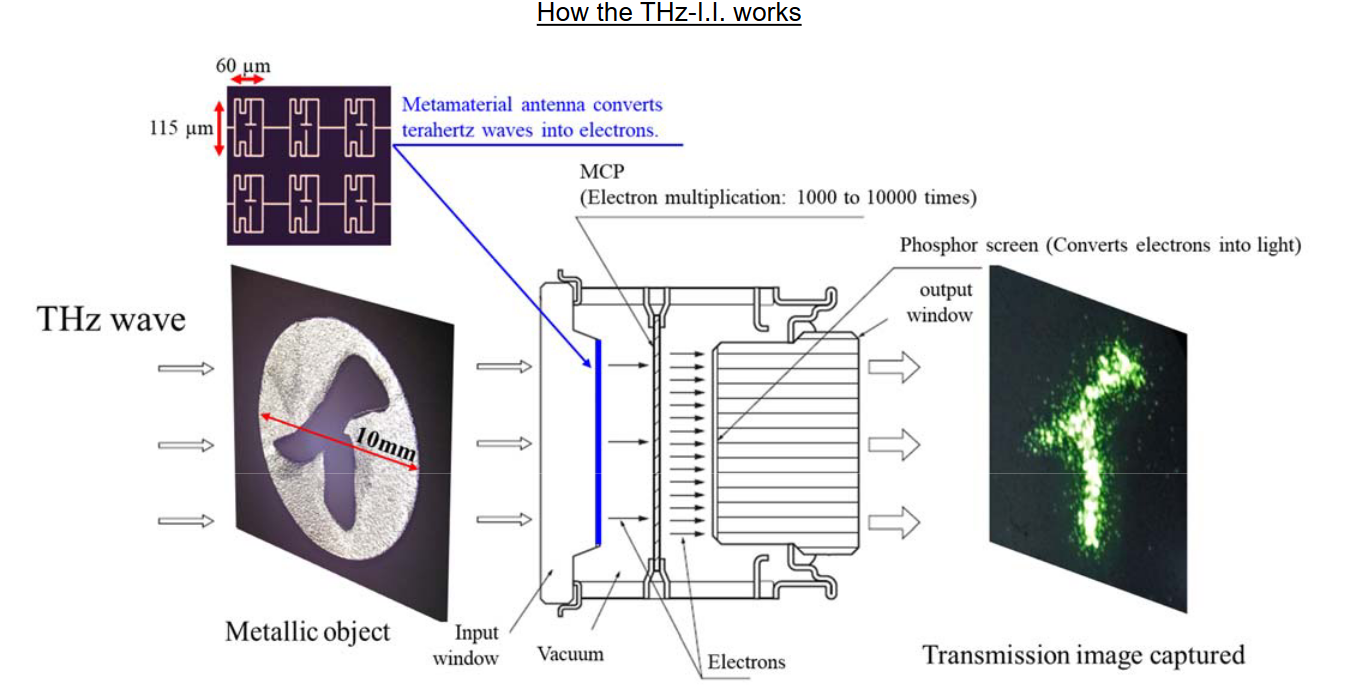

Hamamatsu Develops World’s First THz Image Intensifier

Image Sensors World Go to the original article...

Hamamatsu Photonics has developed the world’s first terahertz image intensifier (THz image intensifier or simply THz-I.I.) by leveraging its imaging technology fostered over many years. This THz-I.I. has high resolution and fast response which allows for real-time imaging of terahertz wave (*) pulses transmitted through or reflected from target objects.

This THz-I.I. will be unveiled at “The 69th JSAP (Japan Society of Applied Physics) Spring Meeting” held at the Sagamihara Campus of Aoyama Gakuin University (in Sagamihara City, Kanagawa Prefecture, Japan) for 5 days from Tuesday, March 22 to Saturday, March 26.

Terahertz waves are electromagnetic waves near a frequency of 1 THz and have the properties of both light and radio waves.

Full press release: https://www.hamamatsu.com/content/dam/hamamatsu-photonics/sites/documents/01_HQ/01_news/01_news_2022/2022_03_14_en.pdf

Nikon Z9 review so far

Canon celebrates 19th consecutive year of No. 1 share of global interchangeable-lens digital camera market

[Updated] 2022 International SPAD Sensor Workshop Final Program Available

Image Sensors World Go to the original article...

About ISSW 2022

Devices | Architectures | Applications

The International SPAD Sensor Workshop focuses on the study, modeling, design, fabrication, and characterization of SPAD sensors. The workshop welcomes all researchers, practitioners, and educators interested in SPADs, SPAD imagers, and associated applications, not only in imaging but also in other fields.

The third edition of the workshop will gather experts in all areas of SPADs and SPAD related applications using Internet virtual conference technology. The program is under development, expect three full days of with over 40 speakers from all over the world. This edition is sponsored by ams OSRAM.

Workshop website: https://issw2022.at/

Final program: https://issw2022.at/wp-content/uploads/2022/03/amsOSRAM_ISSW22_Program_3003.pdf

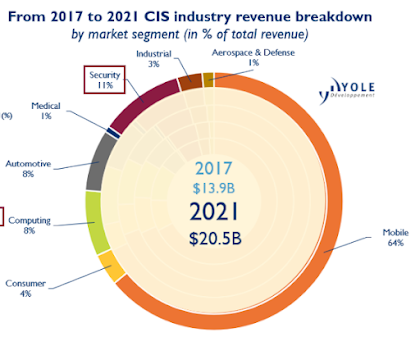

State of the Image Sensor Market

Image Sensors World Go to the original article...

Sigmaintell report on smartphone image sensors

According to Sigmaintell, the global mobile phone image sensor shipments in 2021 will be approximately 5.37B units, a YoY decrease of about 11.8%; among which, the global mobile phone image sensor shipments in 4Q21 will be about 1.37B units, a YoY decrease. About 25.3%. At the same time, it is estimated that the global mobile phone image sensor shipments will be about 5.50B in 2022, a year-on-year increase of about 2.5%. In 1H21, due to the long ramp-up cycle of ultra-high pixel production capacity and the squeeze of low-end pixel production capacity by other applications, there was a short-term structural imbalance and market price fluctuations rose. In 2H21, the production capacity of Samsung and Sony’s external foundries was released steadily and significantly, but the sales in the terminal market were lower than expected and the stocking plan was lowered again, resulting in an oversupply in the overall image sensor market.

Business Korea report about Samsung CIS foundry capacity expansion

Yole announces a new edition of its "Imaging for Security" Market report

Yole announces a new edition of its "Imaging for Automotive" market report

Strategy Analytics estimates USD15.1B global smartphone image sensor market in 2021

According to Strategy Analytics, the global smartphone Image sensor market in 2021 secured a total revenue of USD15.1B. Strategy Analytics finds that the smartphone image sensor market witnessed a revenue growth of more than 3% YoY in 2021. Sony Semiconductor Solutions topped with 45% revenue share followed by Samsung System LSI and OmniVision in 2021. The top 3 vendors captured nearly 83% revenue share in the global smartphone image sensor market in 2021. In terms of smartphone multi-camera application, Image sensors for Depth and Macro application reached 30 percent share while those for Ultrawide application exceeded 15% share.

ijiwei Insights predicts drop in mobile phone camera prices

In 2022, some manufacturers will reportedly reduce the price of mobile phone camera CIS several times. Currently, the cost down of phone camera CIS has penetrated into the camera chip products of 2MP, 5MP and 8MP. Among them, the unit price of 2MP and 5MP mobile phone camera CIS fell by about 20% and more than 30% year-on-year, respectively. [source]

New 3D Imaging Method for Microscopes

Image Sensors World Go to the original article...

New method for high resolution three dimension microscopic imaging being explored.Metasurface-based bijective illumination collection imaging provides high-resolution tomography in three dimensions (Masoud Pahlevaninezhad, Yao-Wei Huang , Majid Pahlevani , Brett Bouma, Melissa J. Suter , Federico Capasso and Hamid Pahlevaninezhad )

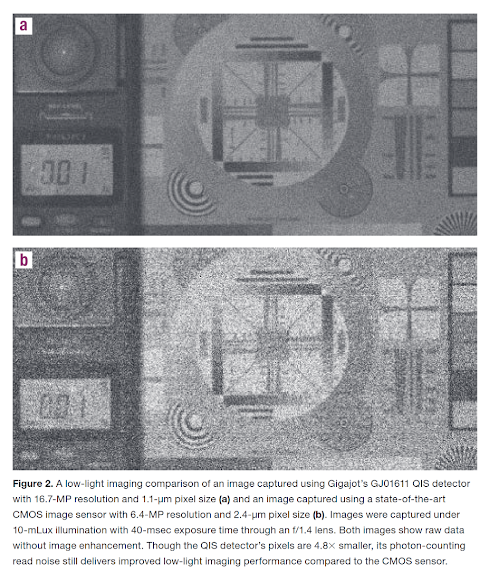

Photonics Spectra article about Gigajot’s QIS Tech

Image Sensors World Go to the original article...

The March 2022 edition of Photonics Spectra magazine has an interesting article titled "Photon-Counting CMOS Sensors: Extend Frontiers in Scientific Imaging" by Dakota Robledo, Ph.D., senior image sensor scientist at Gigajot Technology.

While CMOS imagers have evolved significantly since the 1960s, photon-counting sensitivity has still required the use of specialized sensors that often come with detrimental drawbacks. This changed recently with the emergence of new quanta image sensor (QIS) technology, which pushes CMOS imaging capabilities to their fundamental limit while also delivering high-resolution, high-speed, and low-power linear photon counting at room temperature. First proposed in 2005 by Eric Fossum, who pioneered the CMOS imaging sensor, the QIS paradigm envisioned a large array of specialized pixels, called jots, that are able to accurately detect single photons at a very fast frame rate . The technology’s unique combination of high resolution, high sensitivity, and high frame rate enables imaging capabilities that were previously impossible to achieve. The concept was also expanded further to include multibit QIS, wherein the jots can reliably enumerate more than a single photon. As a result, quanta image sensors can be used in higher light scenarios, versus other single-photon detectors, without saturating the pixels. The multibit QIS concept has already resulted in new sensor architectures using photon number resolution, with sufficient photon capacity for high-dynamic-range imaging, and the ability to achieve competitive frame rates.

The photon-counting error rate of a detector is often quantified by the bit error rate. The broadening of signals associated with various photo charge numbers causes the peaks and valleys in the overall distribution to become less distinct, and eventually to be indistinguishable. The bit error rate measures the fraction of false positive and false negative photon counts compared to the total photon count in each signal bin. Figure 4 shows the predicted bit error rate of a detector as a function of the read noise, which demonstrates the rapid rate reduction that occurs for very low-noise sensors.

The article ends with a qualitative comparison between three popular single-photon image sensor technologies.

Interestingly, SPADs are listed as "No Photon Number Resolution" and "Low Manufacturability". It may be worth referring to previous blog posts for different perspectives on this issue. [1] [2] [3]

Full article available here: https://www.photonicsspectra-digital.com/photonicsspectra/march_2022/MobilePagedReplica.action?pm=1&folio=50#pg50

Axcelis to ship its processing tool to multiple CMOS image sensor manufacturers

Image Sensors World Go to the original article...

BEVERLY, Mass., March 17, 2022 /PRNewswire/ -- Axcelis Technologies, Inc. (Nasdaq: ACLS), a leading supplier of innovative, high-productivity solutions for the semiconductor industry, announced today that it has shipped multiple Purion VXE™ high energy systems to multiple leading CMOS image sensor manufacturers located in Asia. The Purion VXE is an extended energy range solution for the industry leading Purion XE™ high energy implanter.

President and CEO Mary Puma commented, "We continue to maintain a leading position in the image sensor market. Our growth in this segment is clear and sustainable, and is tied to long-term trends in demand for products in the growing IoT, mobile and automotive markets. The Purion VXE was designed to address the specific needs of customers developing and manufacturing the most advanced CMOS image sensors, and has quickly become the process tool of record for image sensor manufacturers."

Canon announces donation to support humanitarian efforts for Ukraine

Canon develops new technology for DR control software that utilizes AI technology to reduce digital radiography image noise by up to 50% compared with Canon’s conventional image processing technology

CMOS SPAD SoC for Fluorescence Imaging

Image Sensors World Go to the original article...

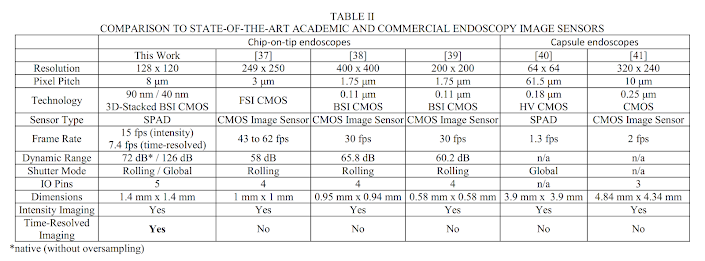

Hot off the press! An article titled "A High Dynamic Range 128 x 120 3-D Stacked CMOS SPAD Image Sensor SoC for Fluorescence Microendoscopy" from the research group at The University of Edinburgh and STMicroelectronics is now available for early access in the IEEE Journal of Solid-State Circuits.

Full article is available here: https://ieeexplore.ieee.org/document/9723499A miniaturized 1.4 mm x 1.4 mm, 128 x 120 single-photon avalanche diode (SPAD) image sensor with a five-wire interface is designed for time-resolved fluorescence microendoscopy. This is the first endoscopic chip-on-tip sensor capable of fluorescence lifetime imaging microscopy (FLIM). The sensor provides a novel, compact means to extend the photon counting dynamic range (DR) by partitioning the required bit depth between in-pixel counters and off-pixel noiseless frame summation. The sensor is implemented in STMicroelectronics 40-/90-nm 3-D-stacked backside-illuminated (BSI) CMOS process with 8-μm pixels and 45% fill factor. The sensor capabilities are demonstrated through FLIM examples, including ex vivo human lung tissue, obtained at video rate.

Open access version: https://www.pure.ed.ac.uk/ws/portalfiles/portal/252858429/JSSC_acceptedFeb2022.pdf

Sony FE PZ 16-35mm f4 G review

Future Era of Robotics and Metaverse

Image Sensors World Go to the original article...

SK hynix discusses what a robotic future may look like and the role of ToF imaging."We will soon witness an era where all households will have at least one robot that looks like it appeared in the scenes of a sci-fi movie like Star Wars."

Image Sensors Europe – Event Agenda Announcement

Image Sensors World Go to the original article...

The Image Sensor Europe team announced details about the upcoming event.

2022 Event Topics Include (agenda link):

| Topic | Speaker |

|---|---|

| IMAGE SENSOR MANUFACTURING TRENDS AND BUSINESS UPDATES | Markus Cappellaro |

| Emerging from the global semiconductor shortage, what is the near-term outlook of the CIS industry? | Florian Domengie |

| Sony's contribution to the smarter industry - technology trends and future prospects for imaging and sensing devices | Amos Fenigstein Ph.D. |

| Panel discussion: how is the IS supply chain responding to sustainability and the green agenda? | |

| TECHNOLOGY FUTURES – LOOKING OUTSIDE THE BOX | Anders Johannesson |

| Efficiently detecting photon energy. The spin out from astronomy to industry has been paradigm shifting in the past – will this happen again? | Kieran O'Brien |

| Angular dependency of light sensitivity and parasitic light sensitivity | Albert Theuwissen |

| Augmented reality – the next frontier of image sensors and compute systems | Dr Chiao Liu |

| Sensing solutions for in cabin monitoring | Tomas Geurts |

| Global shutter sensors with single-exposure high dynamic range | Dr. Guang Yang |

| High resolution 4K HDR image sensors for security, VR/AR, automotive, and other emerging applications | David Mills |

| Bringing colour night vision and HDR image sensors to consumers and professionals | Dr Saleh Masoodian |

| Spectral sensing for mobile devices | Jonathan Borremans |

| Making infrared imaging more accessible with quantum dots | Jiwon Lee |

| Release 4 of the EMVA 1288 standard: adapted and extended to modern image sensors | Prof. Dr. Bernd Jähne |

| Design, characterisation and application of indirect time-of-flight sensor for machine vision | Dr. Xinyang Wang |

| Addressing the challenges in sustainability and security with low-power depth sensing | Dr Sara Pellegrini, Cedric Tubert |

| Establishing LiDAR standards for safe level 3 automated driving | Oren Buskila |

| Modelling and realisation of a SPAD-based LIDAR image sensor for space applications | Alessandro Tontini |

| Low-power Always-on Camera (AoC) architecture with AP-centric clock and 2-way communications | Soo-Yong Kim |

| Resolution of cinesensors: why higher resolution does not always improve image quality | Michael Cieslinsk |

| Latest developments in high-speed imaging for industrial and scientific applications | Jeroen Hoet |

| Event-based sensors – from promise to products | Luca Verre |

| Development of OPD innovative application, such as fingerprint behind display or standalone biometry solutions | Camille Dupoiron |

| Medical applications roundtable | Renato Turchetta |

Sony standardization efforts

Image Sensors World Go to the original article...

Sony presents its effort to make its proprietary image sensor interface SLVS-EC a new international standard. Here's an excerpt from a recently published interview with K. Koide, M. Akahide, and H. Takahashi of the Sony Semiconductor Solutions group.

Koide:I work in the standardization for the mobility area. Products in this category, such as automobiles, are strictly regulated by laws and regulations because of their immediate implications to society, the natural environment, and economic activities as well as to people’s lives and assets. Therefore, products that fail to comply with these laws and regulations cannot even make it to the market. On top of the compliance as a prerequisite, safety must be ensured. This “safety” requires cooperation of diverse stakeholders, from those who are involved in car manufacturing, automotive components, and transport infrastructure such as road systems to road users and local residents. My responsibilities include identifying the rules to be established in order to ensure safety as well as considering the domains and technology relevant to the rules where SSS Group can make its contributions and preparing our business strategies ready for the implementation.

Takahashi:I am involved in the standardization concerning the telecommunication of mobile devices like smartphones and automotive mobility devices. The telecommunication requires the transmitter and the receiver of signals use the same language, and standardization is essential for this reason. The telecommunication subgroup is standardizing the protocol, process, and electronic signal concerning the communication between an image sensor and processor.

Akahide:Like Takahashi-san, I am working on the standardization of image sensor interfaces. This is intended for image sensors for industrial applications. I was invited to work with the Japan Industrial Imaging Association (JIIA) on standardization because they wanted to standardize our SLVS-EC, a high-speed interface which SSS Group developed. As mentioned earlier, interfaces would be worth very little if they were not adopted widely. I believe that this standardization is very important for us, too, so that our high-speed interface will be diffused. At the same time, it is also important to develop a strategy for the future success of the product by determining what to be made open and what should be kept closed.

Koide:The world is growing more complex, and the COVID-19 pandemic is causing more uncertainties. Against this backdrop, there are serious discussions in progress about digitizing road systems, realizing zero-emission vehicles, and so on. The mobility industry is now experiencing a major social paradigm shift. At times like these, what we have for solidarity is order and rules to attain a better world. It is very important to understand these order and rules without prejudice, and to do this, we must engage with the world outside our boundaries, observing and understanding the world from their point of view. I believe that the activities with the mobility industry, including the initiative for developing the international standards, are valuable for me in this sense. For I am engaged in activities for the mobility industry, providing society with safety and security should be my priority. I will therefore continue my best efforts in this standardization initiative while also contributing to the business growth of our company.

Takahashi:For me, it will be making appropriate rules. There is a well-known episode about the washing machines. In 2001, Singapore suspended importing Japanese top-loading washing machines with a spinning drum. The reason for this was that these products did not comply with the international standards. They surely complied with the Japanese industrial standards, but not the international standards, which were based on IEC standards for front-loading single-drum machines popular in Europe and America. Rules have the power to control. As a chair, I would like to pursue making rules that are appropriate and that do not work against SSS Group.

From a more specific viewpoint, there is the issue concerning image sensors. They are increasingly sophisticated that captured image data can be edited easily, boosting the added value of the sensors. However, there was a problematic incident. When a major earthquake hit Kumamoto, someone uploaded on social media a fake video footage of a lion set loose from the local zoo, which many people believed. Security will be important about camera information in the future, and it is necessary to be able to verify the authenticity of images. I hope that new standards will be established to help prevent fake images such as this from being circulated.

Akahide:Joining the SDO has made me realize that everyone has high hopes for SSS Group. My next step will be dedicated to the standardization of our technology and, also as a vice leader of the Global Standardization Advancement Committee, I should be making contributions to the machine vision sector.

The interview does not provide any technical information about SLVS-EC and how it differs from the MIPI M-PHY standard.

Full interview available here: https://www.sony-semicon.co.jp/e/feature/2022031801.html