Image Sensors World Go to the original article...

Sony presents an HDR counter & time stamp-based approach for SPAD sensors:Archives for February 2021

ISSCC 2021: Sony SPAD-Based HDR Sensor

ISSCC 2021: Samsung 0.64um Pixel

Image Sensors World Go to the original article...

This year, ISSCC has not released its usual media kit with preview snippets of the most interesting papers. So, I'm filling the void with few such snippets. The first one is about Samsung 0.64um pixel:Ricoh Explains Importance of Low-Ripple Supply for Image Sensors

Image Sensors World Go to the original article...

Ricoh publishes a video explaining the importance of low ripple supply for CMOS sensors:Pointcloud Inc. and University of Southampton Publish Nature Paper on their Coherent 3D Imager

Image Sensors World Go to the original article...

A Nature paper "A universal 3D imaging sensor on a silicon photonics platform" by Christopher Rogers, Alexander Y. Piggott, David J. Thomson, Robert F. Wiser, Ion E. Opris, Steven A. Fortune, Andrew J. Compston, Alexander Gondarenko, Fanfan Meng, Xia Chen, Graham T. Reed & Remus Nicolaescu from San Francisco-based Pointcloud Inc. and UK University of Southampton appears to be a minor version of their Arxiv.org paper published in August 2020.

Samsung Explains its Smart-ISO Pro

Image Sensors World Go to the original article...

Samsung publishes a promotional video explaining its Smart-ISO Pro feature:Smartsens Presents its Global Shutter Sensor Plans

Image Sensors World Go to the original article...

EET-China publishes Smartsens article on the company's machine vision sensors evolution:

Teledyne Trumpets a New Era in Large Area CMOS Imaging

Image Sensors World Go to the original article...

GlobeNewsWire: Teledyne Imaging (former Princeton Instruments group) introduces LACera technology said to be "a significant step forward in CMOS capabilities for advanced imaging which will enable the next generation of scientific discovery."NIT Announces Novel Stacking Technology for InGaAs to ROIC Bonding

Image Sensors World Go to the original article...

New Imaging Technologies announces the release of several new SWIR sensors now produced with NIT in-house designed stacking technology, internally named NH.ON Semi Unveils Low Power Smart Shot Camera

Image Sensors World Go to the original article...

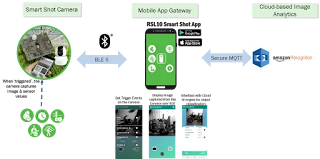

BusinessWire: ON Semiconductor introduces the RSL10 Smart Shot Camera, combining cloud-based AI with ultra-low-power image capture and recognition for IoT endpoints. The camera is based on ARX3A0 CMOS sensor with 560 x 560 pixel resolution, 2.2um pixel size, and a frame rate up to 360 fps. The sensor has an innovative super low power mode which draws less than 3.2 mW while active, and can detect motion or changes in lighting conditions and wake the rest of the system up.Albert Theuwissen Delivers Keynote at IEEE Sensors 2020: DTI is Here to Stay!

Image Sensors World Go to the original article...

Albert Theuwissen delivered a keynote at 2020 IEEE Sensors conference titled "Deep-Trench Isolation is Here to Stay!" Below is a video recording of the keynote:SMIC to Benefit from Increased Demand to its 40nm and 65nm CIS Process

Image Sensors World Go to the original article...

Wccftech: Goldman Sachs believes that SMIC is poised to benefit from the demand increase for image sensors on the 40nm to 65nm process nodes.Do Event-Based Imagers Have Advantage over Regular Global Shutter Ones?

Image Sensors World Go to the original article...

A team of researchers from Czech Institute of Informatics, Robotics and Cybernetics, Czech Technical University in Prague, and University of Defence, Brno, Czech Republic, publishes an interesting MDPI paper "Experimental Comparison between Event and Global Shutter Cameras" by Ondřej Holešovský, Radoslav Škoviera, Václav Hlaváč, and Roman Vítek.TED Special Issue on Image Sensors

Image Sensors World Go to the original article...

IEEE updates the instructions for paper submission for Special Issue of IEEE Transactions on Electron Devices on “Solid-State Image Sensors” to be published in June 2022:PD Field Engineering for Fast and Complete Charge Transfer

Image Sensors World Go to the original article...

Iran University of Science and Technology, Tehran, publishes an arxiv.org paper "A Simulation Study of Electric Field Engineering with Multi-Level Pinned Photodiodes for Fast and Complete Charge Transfer" by Hamzeh Alaibakhsh, Mohammad Azim Karami.Flat Lens News: Metalenz, KAIST

Image Sensors World Go to the original article...

Techcrunch: Metalenz raises $10M in series A investment to productize flat lens for camera module. “We’re really using all standard semiconductor processes and materials here, the exact same equipment — but with lenses instead of electronics,” said Rob Devlin, the company's founder and CEO. “We can already make a million lenses a day with our foundry partners.”Sony Expects its Mobile CIS Business to Return to Growth in 1-2 Years

Image Sensors World Go to the original article...

SeekingAlpha publishes Sony earnings call transcript that gives few more details about the company's CIS business. Sony expects its mobile image sensor business to get back to the growth trajectory in the fiscal year ending on March 31, 2023:Himax Reports 2020 Results

Image Sensors World Go to the original article...

GlobeNewsWire: Himax updates about its image sensor business:Sony Reports 10% CIS Sales Drop, Rises Full Year Forecast

Image Sensors World Go to the original article...

Sony reports its quarterly results and updates forecast for its fiscal year ending on March 31. The quarterly CIS sales dropped by 10% due to the lower mobile phone sensor sales and cheaper product mix. However, the forecast for the full year has been revised upward due to resumption of sales to Huawei that were stopped in September 2020. So, the full fiscal year sales are expected to drop by only 5%:Sony Global Shutter Sensor Designers Interview

Image Sensors World Go to the original article...

Sony publishes a large interview with its global shutter image sensor designers titled "Pregius S—to be a bridgehead for pioneering new markets such as robot arms through the pursuit of high speed, multi-pixel as well as size reduction." Few quotes:ON Semi Reports CIS Sales Growth

Image Sensors World Go to the original article...

ON Semi reports its Q4 2020 results with image sensor sales showing about 4.3% growth over the same quarter in 2019:ON Semi Reports CIS Sales Growth

Image Sensors World Go to the original article...

ON Semi reports its Q4 2020 results with image sensor sales showing about 4.3% growth over the same quarter in 2019: